Principles of Rotary Drying

The directly heated rotary dryer operates on the principle of

lifting and showering the product through a hot gas stream moving.

The efficiency of the dryer is largely dependant on the

differential between the inlet and exhaust gas temperatures,

although the heat transfer rate is also influenced by the

relationship between the design of flights and the speed of

rotation. However, irrespective of the gas and material

temperatures the drying (or residence) time may be critical, as

this is governed by the rate of diffusion of water from the core to

the surface of the material.

For greater thermal efficiency and where inertization is required,

recycling of exhaust gases can be used. This can be implemented on

all our airstream drying systems and retrofitted on customer's

existing drying operations.

For special applications, the rotary cascade design is adapted to

provide a shortfall, or 'Cruciform', lifter configuration.

Co-Current Rotary Dryers are the most widely used and are particularly suitable for drying

materials containing a high moisture content, which are heat

sensitive or have a tendency to stick or cake.

The wet material is in contact with the gas at its highest

temperature, which rapidly evaporates surface moisture. The initial

heat transfer rate is high, causing an immediate and considerable

drop in gas temperature, which prevents overheating of the material

and the dryer shell. The final product is in contact with the gas

at its lowest temperature, enabling the moisture content to be

readily controlled, usually by maintaining the dryer exhaust gas

temperature at a pre-set value.

Co-Current Rotary Dryers Features

Wet material is in contact with the gas at its highest temperature,

which rapidly evaporates surface moisture

The final product is in contact with the gas at its lowest

temperature

Co-Current Rotary Dryers Benefits

Initial heat transfer rate is high, causing an immediate and

considerable drop in gas temperature, which prevents overheating of

the material and the dryer shell; co-current dryers are

particularly suitable for drying materials containing a high

moisture content

Enables the moisture content to be readily controlled

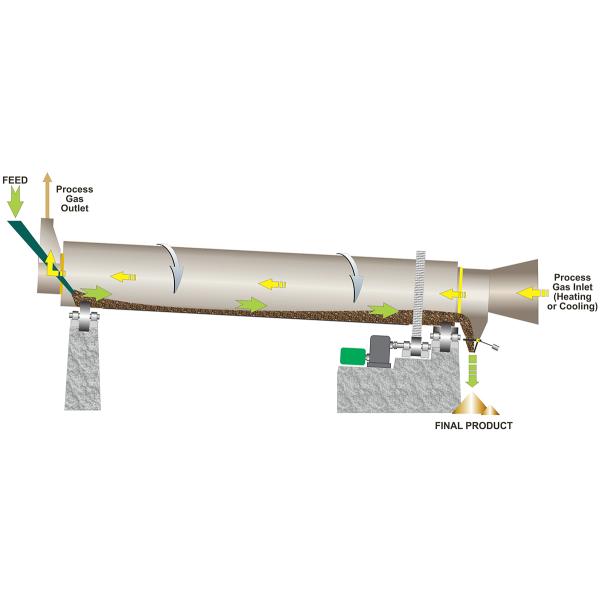

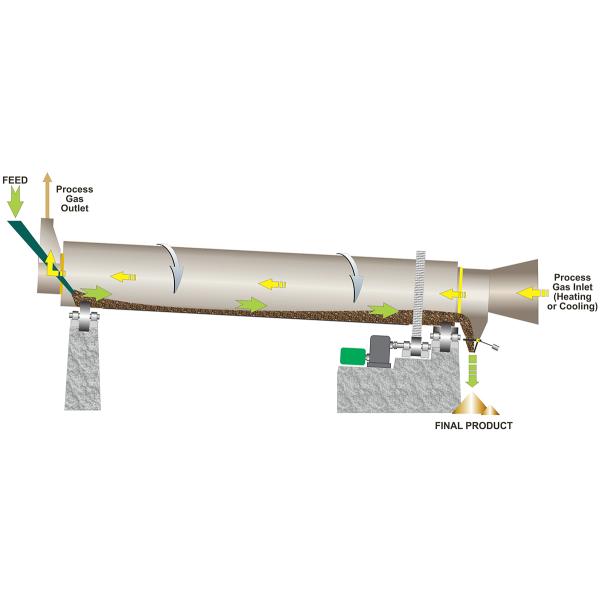

Co-Current Rotary Dryers Process Flow Diagram

Co-Current Rotary Dryers Technical Details

Diameter: 600mm to 3500mm

Length: 8000mm to 65 000mm

Methods of heating: Direct or indirect

Capacity: 500kg/h to 175t/h

Fuel: coal, natural gas, heavy oil, etc

Temp range: 200-700°C

Material: Carbon steel, Stainless steel, etc

Thickness: 8mm to 70mm